Wet Sponge Pinhole Detector

Price 50 INR/ Unit

Wet Sponge Pinhole Detector Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About Wet Sponge Pinhole Detector

Wet Sponge Pinhole Detector

This is also known as Wet Sponge Holiday Detector or Wet Sponge Pinhole Detector or Low Voltage Holiday Detector. The multi-voltage pinhole detector, which uses the wet sponge principle to detect through pinholes, cracks and damaged areas in protective coatings up to a maximum thickness of 500 microns. Pinhole Detectors or wet sponge tester detects pinholes, voids, thin spots, foreign inclusions, or contamination in coatings film. Dielectric strength of film also referred as holiday detection.

Model PD-990 is a low voltage holiday detector / wet sponge tester operation is by the application of a wet sponge to the coating. The wetting agent penetrates any pinhole and makes a conductive path through to the substrate, the pin hole detector automatically detects this conductive path and sounds an audible alarm and also gives a visual warning by a flashing red indicator that a pinhole fault has been detected. The flaw can now be marked for repair and further testing resumed. Coating on metals prevents to corrode unless a protective coating is applied. Pinholes based on wet sponge method generally caused by air entrapment that is then released from the surface, or by the entrapment of particulates (dust, sand, etc.), which do not stay in place. High voltage holiday detector is used for testing coatings above 500m and low voltage holiday detector (Pinhole Detector ) is used below 500µm of coating on metallc substrates.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Pinhole & Porosity Category

Holiday Detector HD-05

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Measurement Range : 0.5 to 35 kV

Connectivity Type : Wired, with probe

Humidity % : Up to 95%

Temperature Range : 0C to +50C

Holiday Detector - External Spring Electrodes

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Measurement Range : Variable with Electrode Selection

Connectivity Type : Direct Coupling to Detector Unit

Humidity % : 90% RH (NonCondensing)

Temperature Range : 10C to +60C

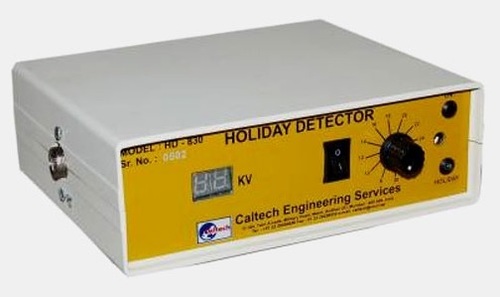

High Voltage Holiday Detector - HD 830

Price 50 INR / Unit

Minimum Order Quantity : 1 Unit

Measurement Range : 1 kV to 30 kV

Connectivity Type : Corded

Humidity % : 85% RH Max

Temperature Range : 0C to 50C

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS