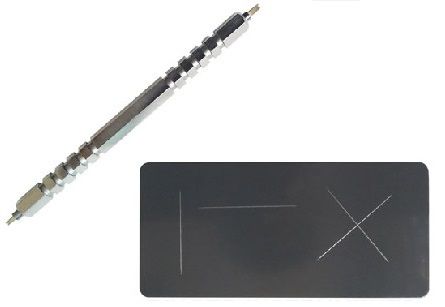

ISO Scratching Tool

Price 50 INR/ Unit

ISO Scratching Tool Specification

- Humidity %

- Suitable for standard lab humidity

- Measurement Range

- Applicable for ISO 1518/ISO 2409 test ranges

- Capacity

- Single tool; manual

- Application Media

- Coated surfaces, paints, varnish

- Protection

- Corrosion resistant finish

- Diameter

- Approx. 1.0 mm tip

- Temperature Range

- Ambient laboratory conditions

- Material

- Stainless steel body, hardened steel tip

- Power Supply

- Manual operation

- Accuracy

- High repeatability, compliant with ISO standards

- Range

- Variable, as per ISO specification

- Finish

- Polished, rust-resistant

- Marking Type

- Cross hatch or linear scratch, as per ISO

- Weight

- Approx. 100 grams

- Tool Dimensions

- Length approx. 120 mm

- Packaged Contents

- Scratching tool, protective case

- Grip Type

- Ergonomic, knurled handle for precise control

- Equipment Type

- ISO Scratching Tool

- Maintenance

- Easy to clean, minimal upkeep required

- Tip Hardness

- Hardened steel, Rockwell > 60 HRC

ISO Scratching Tool Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 500 Units Per Day

- Delivery Time

- 1 Days

- Main Domestic Market

- All India

About ISO Scratching Tool

ISO Scratching Tool

It is be used in according with ISO 17872¼2007, ISO 2063, ISO 7253, BS 7479. There are two shape cutters at one end, and two shape cutters at the other end. All cutters are made of special tungsten steel and can be replaced easily. Having this scratch tool, operator can do shape scratch easily and quickly.

It is equivalent to Elcometer 1537 ISO Scratching Tool.

Outstanding Precision and Durability

Designed for high repeatability and accuracy, the ISO Scratching Tool features a tip hardness exceeding 60 HRC, making it exceptionally durable. Its stainless steel body and rust-resistant finish ensure longevity, even in demanding laboratory environments. This tool complies with ISO standards for reliable performance.

Optimal Ergonomic Design

The ergonomic, knurled handle allows for exceptional grip and control, enabling users to perform linear or cross-hatch scratches with consistency. At approximately 100 grams, the tools weight is balanced to minimize operator fatigue, promoting precise results through comfortable manual operation.

Low Maintenance, High Performance

Maintaining the tool is simple, requiring minimal cleaning effort thanks to its corrosion-resistant polished finish. The robust construction and protective case included in the package provide lasting protection during storage and transit, ensuring the instrument remains ready for accurate coating evaluation at all times.

FAQs of ISO Scratching Tool:

Q: How do I use the ISO Scratching Tool for coating evaluation?

A: To use the tool, grip the ergonomic handle and apply steady manual force to produce either cross-hatch or linear scratches, in accordance with ISO 1518 or ISO 2409 protocols. The 1.0 mm hardened steel tip facilitates consistent marking on coated surfaces, such as paints and varnishes.Q: What is the benefit of the hardened steel tip with Rockwell > 60 HRC?

A: The high hardness rating (>60 HRC) ensures the tip remains sharp and durable, allowing for repeated, precise scratches without deformation, resulting in reliable test outcomes according to ISO specifications.Q: When should I clean and maintain the scratching tool?

A: Routine cleaning after each use is recommended to maintain peak performance. Thanks to its polished, rust-resistant finish and stainless steel construction, maintenance is minimalsimply wipe the tool to remove residue and store in the protective case provided.Q: Where can this ISO Scratching Tool be purchased in India?

A: The tool is available through a range of suppliers, including dealers, distributors, exporters, importers, manufacturers, producers, service providers, and traders operating throughout India.Q: What surfaces and tests is this tool suitable for?

A: Its ideal for coated media, paints, and varnishes, specifically designed for evaluating adhesion and resistance as specified by ISO 1518 and ISO 2409 test ranges in ambient laboratory conditions.Q: What is the process for marking with this tool?

A: Marking can be done by applying manual, controlled pressure to enact either cross-hatch or linear scratches, following the test procedure outlined in relevant ISO standards and ensuring consistent, repeatable results.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Scratch Testers Category

Automatic Scratch Tester

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Capacity : Single sample or multiple sample (optional)

Range : 0 20 N

Measurement Range : 0 20 N load

Resolution : 0.01 N

Manual Scratch Hardness Tester

Price 50 INR / Piece

Minimum Order Quantity : 50 Pieces

Capacity : Single Sample at a Time

Range : 0 10 Newton

Measurement Range : 0 10 Newton

Resolution : 0.1 Newton

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS