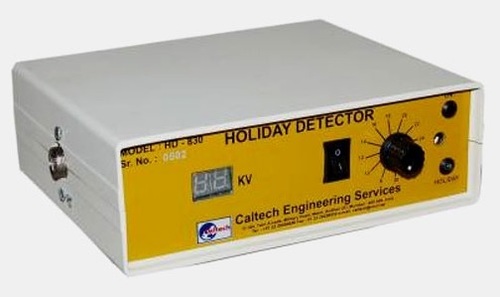

High Voltage Holiday Detector - HD 830

Product Details:

High Voltage Holiday Detector - HD 830 Price And Quantity

- 1 Unit

- 50 INR/Unit

High Voltage Holiday Detector - HD 830 Trade Information

- 500 Unit Per Day

- 1 Days

- All India

Product Description

High Voltage Holiday Detector - HD 830

Holiday detector is used to test and detect pinholes, porosity or flaws in insulated coatings on conductive substrates where coating have to provide an effective safeguard against corrosion. Holiday detector is portable quality control inspection instrument is used to electrically locate and fault find in defects of protective coatings. It is essential that any pinhole, porosity or flaws which will eventually lead to corrosion are detected at the earliest possible stage, preferably immediately after the coating application. Holiday detector is suitable for all types of coatings like fusion bonded epoxy, coal tar epoxy, paints, polyester, polyurethane, pipeline tapes, heat shrinks and asphalt.

Holiday Tester is versatile unit can be used to inspect protective coatings applied to pipelines, tanks, pilings, fire lines or buried pipelines of conductive surface.

Holiday Detector also known as porosity detector or Holiday Tester. A test voltage is applied to the coated pipeline by moving a brush probe across the surface and where there is either a pinhole or flaw the voltage will spark through the coating at the flawed location a red flashing indicator will flash and an audible alarm will sound the detected flaw can now be marked for subsequent repair and testing resumed for the remaining surface area, if no flaws are detected the test will therefore be non-destructive.